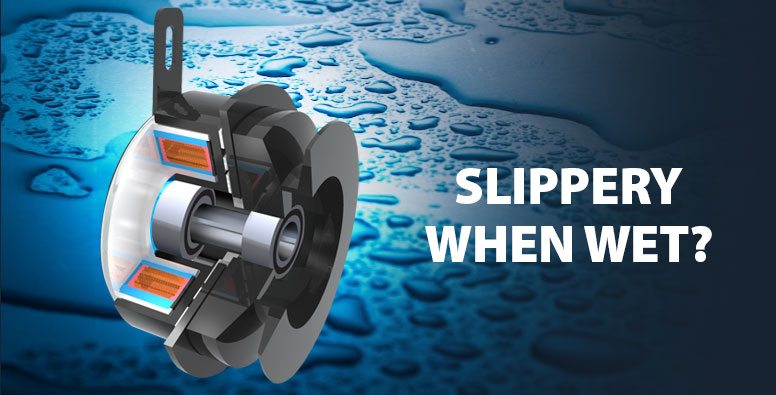

Slippery when wet... does water affect my clutch?

Ogura Mobile & General Purpose clutches, and PTO clutch brakes are designed to operate outdoors.

There are many outdoor applications that benefit from the use of electromagnetic clutches. They are often used for safety, operator convenience, fuel savings, extending product life, and cold weather starting. General Purpose clutches are mostly mounted on engine shafts up to about 40HP, while mobile clutches are mounted directly on pumps and compressors.

The primary concern for outdoor applications is dust and water. Dust is often inevitable, but it should work its way out of contact surface area when the clutch engages. The contact surfaces are steel.

Water is another concern. As opposed to some industrial clutches, there is no friction material used, so we do not need to worry about swelling of materials. These products are coated with Ogura's e-coating that has been perfected after making billions of automotive clutches. It helps prevent rust on the outer surfaces of the clutch. The friction contact surfaces are another story. They will not be coated because this is a wear surface, and it will simply burnish/wear off. Water will lower the immediate coefficient of friction. If the clutch is loaded beyond its torque transfer capacity while wet, it will be prone to slip, therefore it is suggested not to engage the clutch at full load if the clutch is wet. A few cycles at low load and idle speed should generate some heat and dry up the clutch.

If rust develops on the friction surface, it can be burnished to restore it. Some Ogura clutches are used on very demanding applications such as salt and fertilizer spreaders where they often sit for a season while exposed to corrosive agents. When the equipment is put back into service, the surfaces are burnished ready to use again. Burnishing is the process of wearing-in a clutch. It will take off any high spots, including rust. If the clutch is not welded together by the rust, it should be able to cycle and burnish without causing permanent damage. Burnishing should be done at low speed and low load. As cycling generates heat, be sure to let the clutch naturally cool in between cycles. Every machine is different, but 30 to 60 seconds between cycles is generally adequate.

Bearings are sealed to protect from water intrusion. The equipment manufacturer may also protect the seal from high pressure washing by fitting a large washer, spacer, or drive pulley up against the clutch's bearing location.

The brake coil is protected by a high temperature epoxy, keeping water away from the magnet coil.

Connectors should be kept as clean and dry as possible. Some applications use a Weather Pack connector for added dust and moisture protection. If the terminals become rusty and cause an electrical connection issue, try cleaning them and testing the connection again.

For smaller pumps and engines, the Ogura MA Series clutches are available in torques ranging from 58 to 175 lb. ft. For pumps requiring higher horsepower, the MMC Series are rated from 200 to 1500 lb. ft. A variety of bore sizes and pulley options are available from stock.

Benefits of using Ogura Mobile & General Purpose clutches:

- Long life

- Safety and convenience with remote starting

- Fuel and energy savings

- Built for outdoor operation

- Many years of proven success

- Custom designs available based on minimum order quantities

- Reduced engine load on cold weather starts

- Increased operational life of driven equipment

- Simple installation