PTO Clutch Brakes

for Outdoor Power Equipment

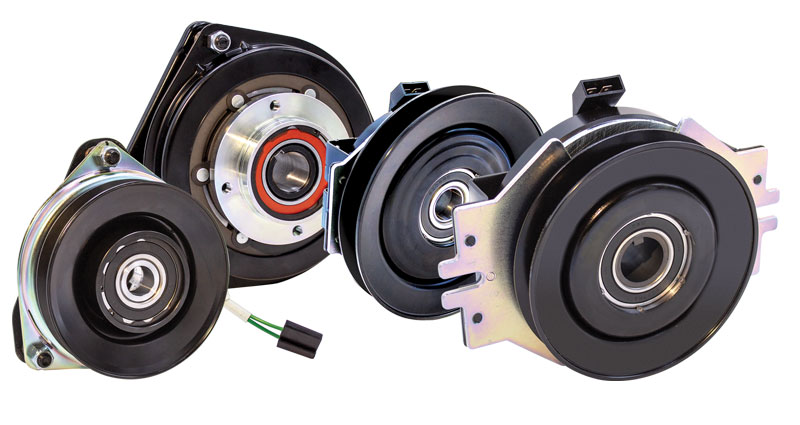

Electromagnetic PTO Clutches

for Outdoor Power EquipmentElectric PTO clutches provide a cost effective, reliable means of mower deck and implement control while increasing operator safety. The latest innovative clutches from Ogura are patented under #US Patent No.: US8,973,727B1.

Ogura manufactures a wide range of electric PTO clutches that are used in riding mowers, zero turn mowers, and commercial walk-behind mowers. Heavy duty models provide extended life in demanding turf care machines such as estate mowers, commercial zero turn mowers, municipal lawn mowers and other grounds keeping machinery.

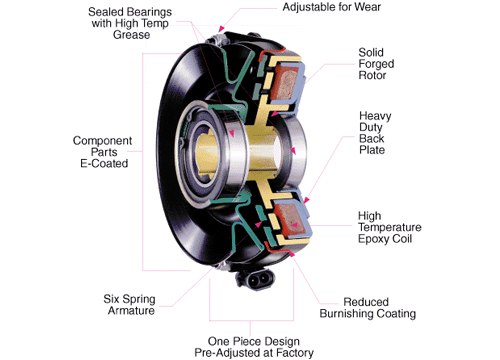

Ogura, heavy duty, electromagnetic PTO clutch brakes provide up to double the life of competitive clutches as they can be adjusted for wear. This provides a considerable cost saving and reduced down time, since the clutch can be adjusted in minutes while on the machine with a standard box wrench.

Electric PTO clutches and clutch brakes are also used to remotely engage the cutting wheel in saw mills, stump grinders and log cutters. They are an important element of “operator presence” controls, where the operator can control the implement at a safe distance.

In addition, Ogura PTO clutches are used in trenchers, seeders, top dressers, fertilizer and herbicide spreaders and sprayers. Cost savings and increase profits can be realized through precise application of seed, chemicals and top soil.

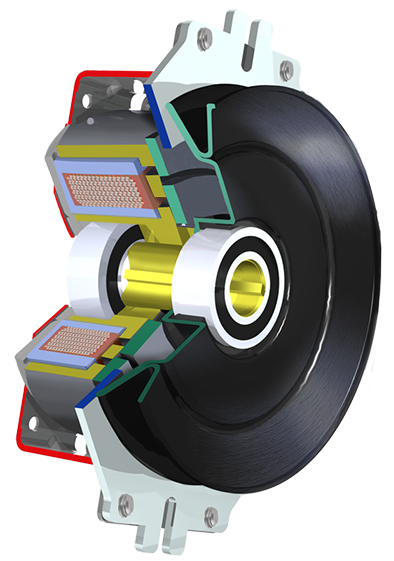

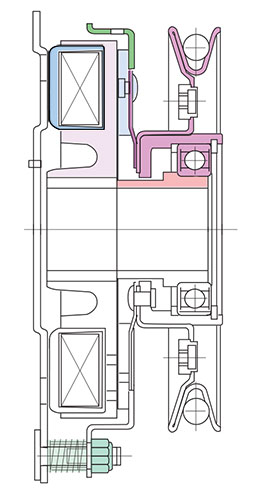

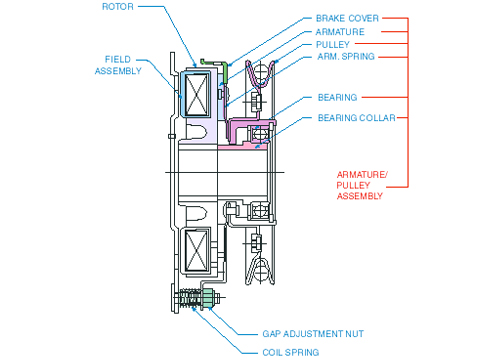

Solid forged rotor

A one piece solid forged rotor means no chance of

internal parts separation. Our rotors also have an even

wall thickness around the coil which gives optimum flux

distribution, maximizing torque.

Lead wire or terminal

Depending upon model and OEM preference, units

can either come with a lead wire, wire protector and

terminal, or have a built-in terminal.

High temperature, longer life grease

All models include our special long life grease which

has shown a significant improvement in life over other

standard high temp greases.

E-coating

Where possible, all parts in the clutch are e-coated to

give maximum corrosion protection.

High temperature epoxy coil

To help prevent failure from both vibration and outside

contaminants, all coils are sealed in the coil shell with a

high temperature epoxy coating.

Heavy duty pulleys

All models use a heavy duty roll formed or machined

steel pulley. A stronger pulley resists damage due to

abusive environments.

Reduced burnishing time

Reduced lighter duty units use a coating on the clutch

face that significantly reduces burnishing time. Higher

torque units come pre burnished to increase out of box

torque.

Soft-start control option

An optional electric soft start control can be added to

produce a softer engagement.