How is an Ogura PTO clutch brake a safety device?

Once considered a premium feature, it is now an industry standard for safety and convenience.

Ogura PTO clutch brakes serve two functions. First, they engage when electrical power is applied. That transfers torque from the driver to whatever is being driven. Secondly, when power is removed, the clutch disengages, and the brake engages. That brake is intended for safety. These clutches are used on residential and commercial riding mowers, but also on outdoor equipment such as stump grinders, concrete cutters, and portable sawmills. As mentioned above, when the electrical power is removed, the clutch disengages and that is when the brake engages for safety. Let's use a zero-turn mower as an example.

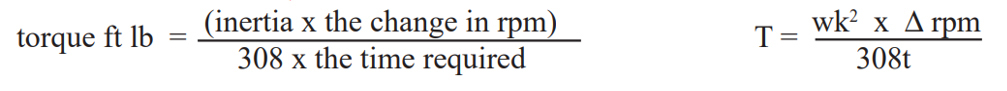

A person is mowing with the clutch engaged. The engine is running, and the clutch has been engaged for mowing. The clutch transfers the torque from the engine to the cutting blades via clutch and belts. The engagement occurs because the coil attracts an armature through electromagnetism, and the pulley/blades then turns in sync with the rotor/engine shaft. When power is removed from the clutch, the clutch coil deactivates which disengages/releases in under one hundred milliseconds.

When power is removed and the clutch disengages, the armature is no longer attracted to the coil body through magnetism. There are leaf springs attached to the armature that pull it away from the coil and toward a brake shroud. The armature, which is connected to the pulley, then rubs against the brake shroud. This is when the braking occurs. Friction occurs through steel-on-steel contact. Internal springs provide the braking force. The force of springs causes friction. The brake torque is small compared to the clutch torque, but it is enough to slow the cutting blades in a timely manner. While the clutch will engage in well under one second, the industry considers under 5 to 7 seconds a safe guideline to slow the blades for safety.

As an industry, guidelines developed over the years to promote safe equipment operation. ANSI B71.1:2012 standard sub clause 22.2 was established. Concisely, it says that new machines are recommended to have a braking device that will help slow the rotating cutting blades to a stop within 5 seconds after the clutch is disengaged. More specifically, it says that it should stop within that time limit for at least the first five thousand cycles.

For commercial mowers, the guidelines are a little less stringent. For those, the seven second rule applies. Again, this is aimed at keeping the operator safe as the blades come to a stop. The ANSI B71.4 standard applies. These machines are typically used by turf care professionals and the machines and decks tend to be larger with higher inertia which leads to stop times slightly longer.

Ogura GT series PTO clutch-brakes are made in a variety of configurations and typically mount on gas and diesel engines rated up to 40 HP. Bore sizes match the typical engine shaft sizes. Pulley sizes can vary based on machine requirements. Some have hub outputs to mount your own pulley, sprocket or coupling half. Clutch torque is rated up to 400 lb-ft on the larger units. These clutches typically operate on 12 or 24VDC.

- Long life

- Safety

- Fuel and energy savings

- Built for outdoor operation

- Many years of proven success

- For use with operator presence controls

- Reduced engine load on cold weather starts

- Available with a soft start controller

- Custom designs available based on minimum order quantities