Want to Avoid a Wobbly Clutch?

We've heard it many times over, "That clutch is wobbly." Proper installation, mating parts and maintenance go a long way. Our PTO clutch brakes are primarily used in the outdoor power equipment market, including consumer and commercial mowers, ag equipment, mobile wood processing equipment, stump grinders, off highway equipment, and more.

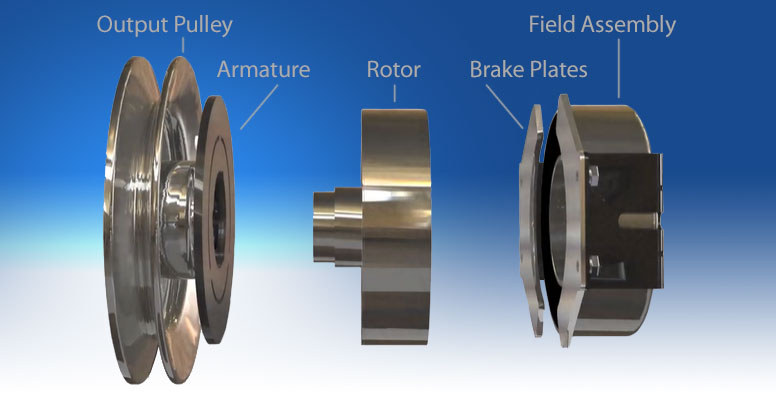

Ogura PTO clutch brakes are shaft mounted and are axially clamped. For most lawn and garden equipment, they are clamped between the drive pulley and the end of the shaft. On the end of the shaft, a center bolt and washer are used. The equipment OEM will specify the proper grade of bolt and required tightening torque. This is important to keep the clutch from loosening up. If high vibrations are expected, the manufacturer may recommend a thread locking compound. With proper clamping force, the assembly is rigid, sturdy and reliable.

As mentioned, the inboard side of the clutch normally mounts against a ground drive pulley. If that pulley surface is worn or not flush where it meets the clutch, then it could cause issues. This could lead to wobbling conditions. Be sure to check these two critical areas if a wobbling issue occurs or when you are installing your clutch.

Ogura GT series PTO clutch-brakes are in made in a variety of configurations and typically mount on gas and diesel engines rated up to 40 HP. Bore sizes match the typical engine shaft sizes. Pulley sizes can vary based on machine requirements. Some have hub outputs to mount your own pulley, sprocket or coupling half. Clutch torque is rated up to 400 lb-ft on the larger units. These clutches typically operate on 12 or 24VDC.

Benefits of using an Ogura PTO clutch brake

- Long life

- Safety

- Built for outdoor operation

- Many years of proven success

- For use with operator presence controls

- Available with a soft start controller

- Custom designs available based on minimum quantities