Why do static or dynamic engagements matter in a clutch or brake?

We must consider changes in torque ratings, and we can't forget max work rates.

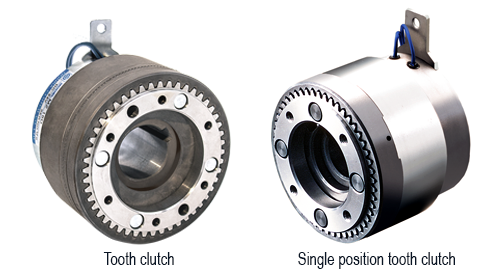

Electromagnetic clutches and brakes are used as motion control devices to engage, disengage, stop, hold, or sometimes provide tension. The tensioning type are a bit unique, so we won't discuss them here. The normal power-on types are used on gates, doors, security systems, packaging, food processing, factory automation, machine tools, and other applications.

Clutches are generally recognized by a static torque rating. This is the torque that the clutch or brake would transfer before it could slip. Aside from the tensioning type of clutch or brake, the device is not intended to slip. If the clutch or brake is engaged at 0 rpm, and if you apply torque below that static torque rating, it shouldn't slip. The ratings are a minimum or worst-case value because of tolerance stacking and manufacturing variations. In most cases the actual torque value can be higher, but for simplicity we call out a minimum value.

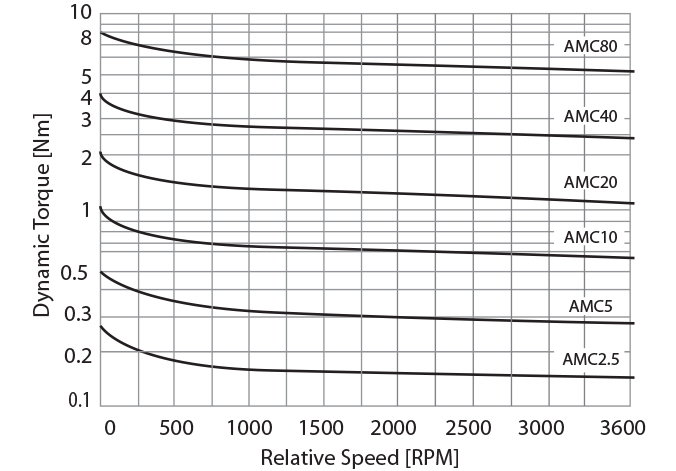

When clutches or brakes engage while the shaft is rotating, it is a different story. We call that dynamic engagement. The static torque rating goes out the window. You must now pay attention to a chart of dynamic torque vs rpm. The clutch or brake will slip momentarily during the dynamic engagement and the torque transfer capability is decreased. If a dynamic torque chart isn't available, you must consult with Ogura for an application review.

For example, here is the chart for AMC clutches. For AMC-10, at 3600 rpm engagement, the torque rating is about 60% of the static torque rating. It starts at 1Nm then ends up around 0.6Nm. This is why we ask for engagement speed when we look at new applications. We must size it for dynamic torque. For products like holding brakes that engage at 0 rpm, we usually just look at static torque rating. The whole industry normally just lists static torque and then you select based on a de-rating for dynamic engagement.

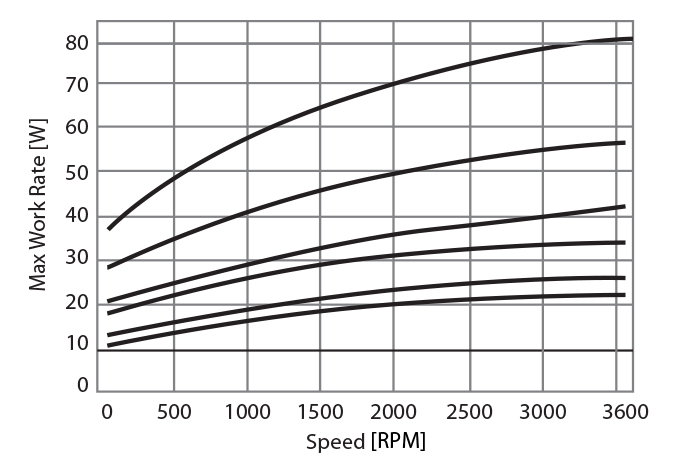

Because dynamic engagements generate heat, there are limits on the max work rate or wattage. The clutch or brake needs time to dissipate that heat. So, in addition to identifying the appropriate dynamic torque, we also need to consider Max Work Rate. Work Rate is Work (Joules) over a certain time period (seconds). Furthermore, Work Rate is dependent upon both inertia and speed. In fact, Work is proportional to RPM^2. It is sometimes required to use a larger clutch or brake when cycle rates are fast, and inertia or RPM is high.

AMB and AMC series brakes and clutches have static torque ratings from 2.2 lb-in (0.25 Nm) to 71 lb-in (8 Nm). There are other series that offer other torque ranges as well. For example, static torque ratings for the V series are 4 lb-ft (6 Nm) to 44 lb-ft (60 Nm).

Benefits of using Ogura AM series clutches or brakes:

- Compact design

- High cycle rates

- High speed capability

- Zero backlash designs

- Current controls torque

- Fast response times

- Long life