Ogura Racing Clutch (ORC) Frequently Asked Questions

Welcome to the Ogura Racing Clutch (ORC) FAQ section, where we address common questions related to our high-performance clutches. Whether you're a seasoned racer or an automotive enthusiast looking to enhance your vehicle's performance, this guide provides essential information about ORC's products, their benefits, and usage. From clutch selection to maintenance tips, we’re here to help you make the most of your ORC experience and ensure optimal performance on the track or street.

What are the different types of ORC reinforced clutch series?

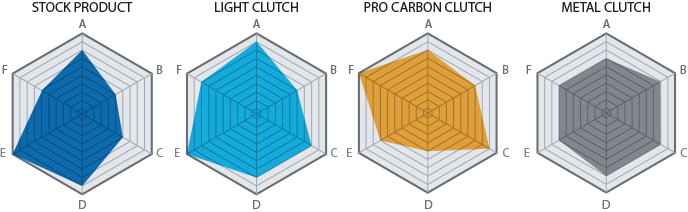

There are three main types: the METAL series, the LIGHT series, and the PRO CARBON series.

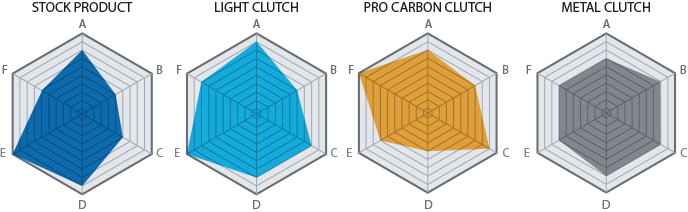

Clutch selection is typically based on a combination of half-clutch usage, heat resistance, life, price, pedal force, and shift feeling. Depending on the product series and options, internal components and construction will vary.

Clutch selection is typically based on a combination of half-clutch usage, heat resistance, life, price, pedal force, and shift feeling. Depending on the product series and options, internal components and construction will vary.

| A | B | C | D | E | F |

|---|---|---|---|---|---|

| Half Clutch | Heat Resistance | Life | Price | Pedal Force | Shift Feeling |

* The life values in the prduct specification radar chart above is based on sports driving.

What are the main differences between single, twin, and triple disc clutches?

Each clutch has a different number of discs, and the more discs you have, the greater the transmission torque.

However, increasing the number of discs does not mean that durability will increase.

* Please select based on the engine power of the vehicle and the intended use.

| Sport | Drift | Circuit | Dag | |

|---|---|---|---|---|

| Light Clutch | ★ | ● | ★ | ► |

| Pro Carbon Clutch | ★ | ► | ★ | ► |

| Metal Clutch Single & Twin |

● | ★ | ★ | ● |

| 1000F | ► | ► | ★ | ★ |

★ Optimal fit ●Good fit ► Not recmmended

Note: The above clutch selection is based on our internal data.

Clutch selection will also vary depending on the actual usage conditions.

For more information, contact your local tuning shop or ORC.

What is the difference between models 309, 409, 559, 659, and 1000F?

The outer diameter and number of discs are the main difference. The model is a numerical value that represents the corresponding horsepower (for reference only).

| Model | HP | Disc OD |

|---|---|---|

| 309 | 300 | 7.9 inches (200mm) |

| 409 | 400 | 8.9 inches (225mm) |

| 559 | 550 | 7.9 inches (200mm) |

| 659 | 650 | 7.9 inches (200mm) |

| 1000F | 1000 | 7.9 inches (200mm) |

* The smaller the outer diameter of the disc, the better the engine response, but the lower the transmission torque. Conversely, the larger the outer diameter of the disc, the greater the transmission torque, but the larger the outer diameter, the larger the inertia (moment of inertia), and the worse the clutch disengagement.

What is the difference between a disc with a damper and without a damper?

The damper on the disc makes the half-clutch easy to use and absorbs vibrations from the transmission. On the other hand, if there is no damper, the weight of the disc alone will be lighter, which will improve the shift feeling (release, etc.), but the half-clutch will be difficult to use and the aggressiveness of the drive will increase.

What is the difference between 559 and 659?

The 659 is a high-pressure version of the 559 with disc OD of 7.9 inches (200mm). The 659 is rated for 650 HP vs 550 HP for the 559 (HP is provided for reference only).

The smaller the outer diameter of the reinforced clutch, the more advantageous it is in inertia and clutch release.

The smaller the outer diameter of the reinforced clutch, the more advantageous it is in inertia and clutch release.

There are vehicles that come with conversion kits, but what is the difference from the car models that come with them?

Depending on the vehicle, there is a pull type clutch and a push type clutch. The main difference is between the pull type (pull-to-release clutch) and the push type (push-to-release clutch). In the case of ORC clutches, all clutches are push-type clutches, so a conversion kit is included to convert from pull to push.

What makes a silent clutch different?

In the case of ORC clutches, the METAL Series and PRO CARBON Series are all lug-drive type clutches. This is a method of transmitting torque by hooking the groove of the pressure plate onto the lug (meaning pillar). This is because when you step on the clutch, the plate is released and the pressure plate comes into contact with a component called the connect shaft, causing a backlash sound. The silent type also has a spring on the flywheel side to reduce this noise. It has a construction that does not generate backlash noise, there is a strap drive method used in the genuine clutch. This is a white belt that secures the clutch cover and pressure plate via a steel strap (belt) to transmit torque.

What is the difference between high µ disc and standard type disc?

What is the difference between high µ disc and standard type disc?

The high µ disc is only available in the 409 Series and it has a higher coefficient of friction than the standard discs. Half-clutching is more severe and the amount of wear is greater than with the standard discs. Because of the properties of the aggressive material, the chance of welding the surfaces increases in high temperature ranges. As it is an abrasive material made primarily for competition use, sufficient care must be taken when using it.

I will be using my clutch for drifting, what should I use?

It depends on the vehicle specifications, but if horsepower is less than 400 horsepower, we recommend the 409 Series. We recommend a twin clutch for over 400 horsepower, but please note that the transmission will be more aggressive.

What clutch is more durable?

Durability varies depending on usage and vehicle specifications. Please note that increasing the number of discs does not mean that the durability of the clutch will increase.

What is the disc wear limit?

For an ORC clutch, the measurement of the new disc is 4.7mm (0.185”). (Excluding some car models) Regarding the wear limit value of the disc, if the total wear amount of parts inside the clutch exceeds 1mm, the pressing force will decrease by about 80%, so the usage limit value should be adjusted accordingly.

Example:

Example:

| For single disc | Flywheel wear amount >> 0.1mm |

| Pressure plate wear amount >>0.1mm | |

| Disc wear amount >>1.2mm | |

| Total wear amount >>1.4mm |

| For twin disc | Flywheel wear amount >>0.1mm |

| Pressure plate wear amount >>0.1mm | |

| Disc 1 wear amount >>0.7mm | |

| Mid plate wear amount >>0.1mm | |

| Disc 2 wear amount >>0.6mm | |

| Total wear amount >>1.6mm |

My clutch is having trouble disengaging, what should I do?

The common cause of clutch disengagement failures is not due to the clutch alone, but due to insufficient pressure on the release. If you feel that the clutch is not releasing properly, we recommend measuring the release stroke and adjusting it before disassembling the clutch.

Release cylinder stroke amount / adjustment value.

*About FD35: Since it is difficult to measure the cylinder stroke amount for this model, please adjust so that the "clutch pedal play" is 0.39 inches (10mm) or less as an alternative. 559 (Metal and Pro Carbon twin) is bearing type B (outer diameter 74). Also, the release cylinder stroke amount is 0.56-0.58 inches (14.2-14.7 mm).

| Car model | Release bearing: | Stroke amount: | |||

|---|---|---|---|---|---|

| Type | Outer diameter (mm) | Contact diameter (mm) | Recommendation (mm) | Upper limit (mm) | |

| R32, R33 | A | ø67 | ø44 | 15.2 | 15.7 |

| R34 | A | ø67 | ø44 | 15.2 | 15.7 |

| PS13 | A | ø67 | ø44 | 15.2 | 15.7 |

| S13 | A | ø67 | ø44 | 15.2 | 15.7 |

| S14 | A | ø67 | ø44 | 15.2 | 15.7 |

| S15 | A | ø67 | ø44 | 15.2 | 15.7 |

| Z32 | A | ø67 | ø44 | 15.2 | 15.7 |

| Z33 | B | ø74 | ø54 | 13.8 | 14.3 |

| JZA80 | B | ø74 | ø54 | 13.8 | 14.3 |

| JZA70 & others | B | ø74 | ø54 | 13.8 | 14.3 |

| SW20 & others | A | ø67 | ø44 | 13 | 13.5 |

| AE86 | A | ø67 | ø44 | 12.5 | 13 |

| SXE10 | A | ø67 | ø44 | 13 | 13.5 |

| EP82 | A | ø67 | ø44 | 13.7 | 14.2 |

| SXE10 | A | ø67 | ø44 | 12.9 | 13.3 |

| EP82 | A | ø67 | ø44 | 12.9 | 13.3 |

| ZZW231 | A | ø67 | ø44 | 12.9 | 13.3 |

| AE92 | A | ø67 | ø44 | 12.9 | 13.3 |

| AE101 | A | ø67 | ø44 | 12.9 | 13.3 |

| EK4 | A | ø67 | ø44 | 12.3 | 12.8 |

| EG6 | A | ø67 | ø44 | 12.3 | 12.8 |

| AP1 | B | ø74 | ø54 | 12.7 | 13.2 |

| ENA14 | B | ø54 | ø54 | 12.3 | 12.7 |

| DC5 | A | ø67 | ø44 | 13 | 13.4 |

| FC3S | A | ø67 | ø44 | 15.4 | 16 |

| NA6CE & others | A | ø67 | ø44 | 14.3 | 14.8 |

| FD3S | A | ø67 | ø44 | 15.6 | 16.2 |

| SE3P | C | ø81 | ø44 | 12.7 | 13.2 |

| CD9A | A | ø67 | ø44 | 13.67 | 14.1 |

| CE9A | A | ø67 | ø44 | 13.67 | 14.1 |

| CE9A & others | B | ø74 | ø54 | 14.3 | 14.8 |

| GC8 | A | ø67 | ø44 | 16 | 16.6 |

| GD8 | C | ø81 | ø62 | 13.4 | 13.9 |

| Manufacturer | Engine Model | Tightening torque lb-ft (Nm) |

|---|---|---|

| Nissan | RB26DETT RB25DE(T) RB20DE(T) CA18DE(T) | 104.8-111 (142.1-151.9) |

| VQ30DE(TT) SR20DE(T) VQ35DE | 61.4-68.7 (83.3-93.1) | |

| Toyota | 1JZ-GE (GTE) 2JZ-GE (GTE) | 86.7 (117.6)) |

| 3S-GE (GTE) 2JZ-GE (GTE) | 79.5 (107.8) | |

| 4E-FTE | 65.1 (88.2) | |

| 4A-GE 1ZZ-FE | 57.8 (78.4) | |

| Honda | B16A B16B B16C | 75.9 (102.9) |

| K20A | 90.1 (122.5) | |

| F20C | 93.7 (127) | |

| C30A C32B | 76 (103) | |

| Mazda | 13BT 13B-REW 13B-MSP | Flywheel mounting bolt 61.4-72.3 (83.3-98.0) |

| Counterweight mounting nut 289.1-361.4 (392-490) | ||

| B6-ZE BP-ZE | 70.9-75.9 (96.1-102.9) | |

| Mitsubishi | 4G63T | 94-101.2 (127.4-137.2) |

| Subaru | EJ20T | 53.5 (72.5) |

Clutch Cover bolt tightening torque chart

| Series | Tightening torque lb-ft (Nm) |

|---|---|

| 309 409 559 659 1000F | 28.1 (39.2) | 609 | 54.2 (73.5) |

The clutch pedal won’t return, what should I do?

In this case, the master cylinder relief point might be misaligned. First of all, we recommend that you adjust the stroke of the release cylinder and at the same time adjust the relief point position of the master cylinder.

I hear a noise coming from my transmission while driving. What is the cause?

The main cause of abnormal noise usually originates from the engine, particularly engines with highest torque at lower speeds. By installing a reinforced clutch, the ORC clutch is lighter in weight compared to a stock clutch, which may cause resonance noise from the transmission. Especially in the case of the high torque, low rpm engine, the noise may feel louder than usual in that torque range. As a recommended measure, using transmission oil with high viscosity can alleviate the resonance noise, but please note that due to mechanical issues, it is not possible to completely silence the sound.